New technological innovations are disrupting every major business sector, and every business process out there. Supply chain management is no exception.

Supply chains are becoming more complex, and yet they are still mostly managed using “old-school” methods – manually and with the help of internal proprietary tools. That’s problematic because customers now demand goods and services to be delivered as fast as possible. Failing to do so results in lost revenues.

In this post, we’ll show how to improve supply chain management using the latest technological innovations. But before we dig in, let’s start with some essential supply chain definitions first.

What is Supply Chain Management?

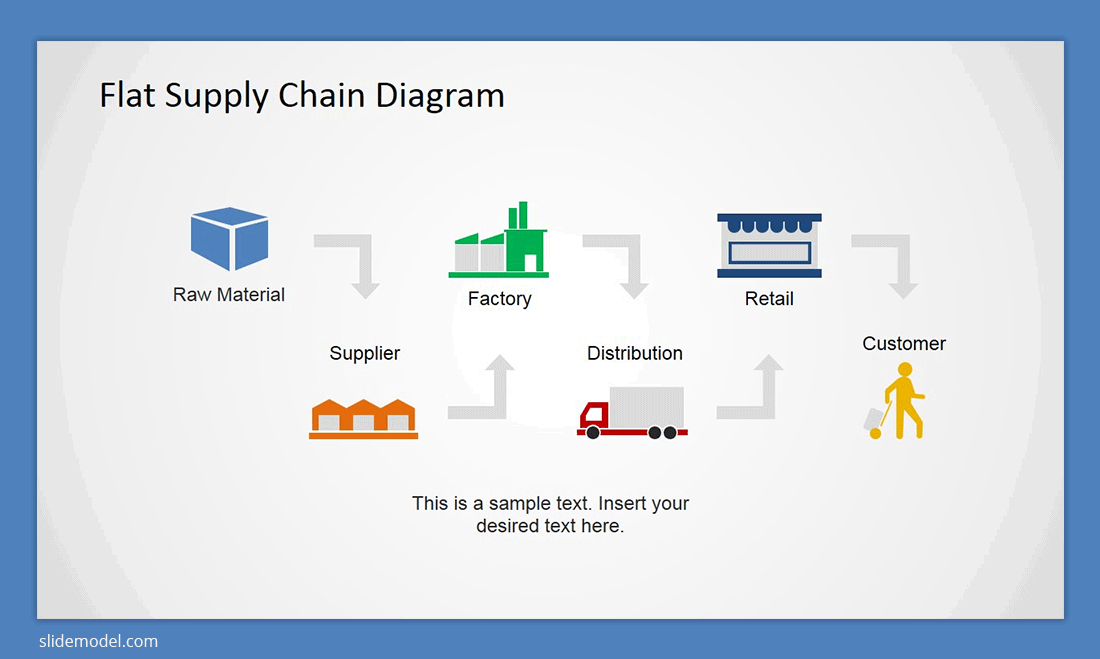

A supply chain is a multi-layer network of entities that work together to source/produce and deliver the commodity to the end-buyer.

Source: Flat Supply Chain Diagram for PowerPoint by SlideModel

Traditional supply chains (as pictured above) are linear with all the processes running from left to right within a given sequence of product flow. And there is a lot of different business process and activities take place before a raw product gets transformed into an actual good and reaches the buyer.

Supply Chain Management (SCM) is the process of optimizing that broad range of activities that are needed to plan, control and execute a product’s flow all through the life-cycle so that the entire process is as streamlined and cost-effective as possible.

In particular, supply chain managers are dealing with various tasks within the next 7 functional areas:

- Purchasing

- Manufacturing

- Inventory Management

- Demand Planning

- Warehousing

- Logistics

- Customer Service

At first, these areas may seem to look like independent functions, but high supply chain efficiency can only be reached when seamless collaboration happens among these. To achieve better levels of interactions, increase transparency in between those functions and improve service levels, most businesses are now considering digitization.

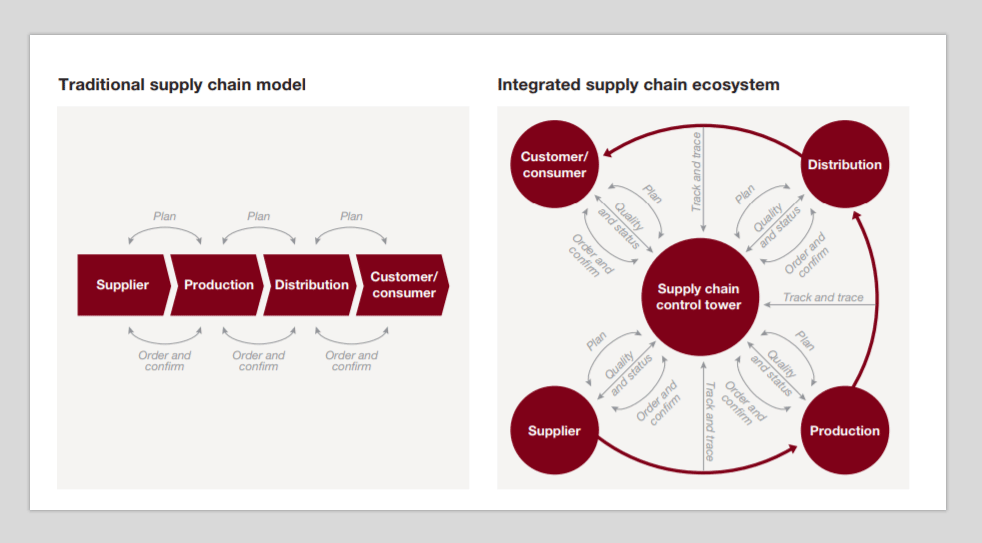

Just what is digitization in the context of the supply chain management? In short, it assumes using new technologies (cloud computing, Big Data analytics, machine learning and IoT) to replace the legacy in-house infrastructure and labor-heavy processes present within each function. The ultimate goal of digitization is to link all the seven functions listed above into one fully integrated global supply chain.

Source: PwC

Digital Supply Chains come with several major benefits:

- More transparent – all the operations and supply chain management run online, meaning that managers can instantly review all aspects of the supply chain. They have a 360-view into who’s doing what, and what products are headed where.

- Better communication and collaboration – the information about all-important supply chain events flow freely between all entrants and is readily available.

- Real-time responsiveness – data about any changes in the supply chain gets instantly transmitted to the entire network. Decisions can be made based on real-time events.

- Flexibility – any change in end-customer demands can be immediately addressed by the supplier.

According to a PwC industry study, 72% of surveyed businesses have already begun the digital transformation of supply chain and expect to finish the digitization process by 2021.

Why Companies are Rushing to Switch to Digital Supply Chain Management

For one, the efficiency in supply chain management has been on a steady decline as chains grow larger in both length and depth. A typical mid-to-enterprise grade supply chain can now contain well over a hundred of participants ranging from suppliers’ suppliers to third-party logistics providers, software vendors, financial organizations and other players. And this network can span over several geographic locations, making effective and timely communication even more challenging.

Maintaining a proper flow of data becomes problematic without the new technology in supply chain management such as cloud computing, predictive analytics and forecasting, blockchain and IoT. All of these combined enable businesses to move the products through the chain faster, with greater efficiencies and a lower cost.

Secondly, 73% of companies also experience increased pressure from consumers, demanding goods and services to be delivered faster than ever. The customer demand levels are changing at a break-neck speed and companies are constantly forced to optimize their supply chain strategy to meet those shifts and remain as competitive as industry leaders in their category.

Just how effective are we speaking? Amazon is just one of the digital supply chain examples showing what kind of logistics management efficiencies business can achieve through digital transformation. The e-commerce giant holds a patent for predictive shipping – products are shipped even before a shopper places the order. Once they do, machine learning algorithms match that order with a shipment that’s already in the logistics network (being transported to the customer’s locale) and the particular product is then re-routed to the customer’s door. In short, that’s how Amazon Prime delivery works. But to get to Amazon’s level, businesses need to undergo the complete digitization in supply chain management.

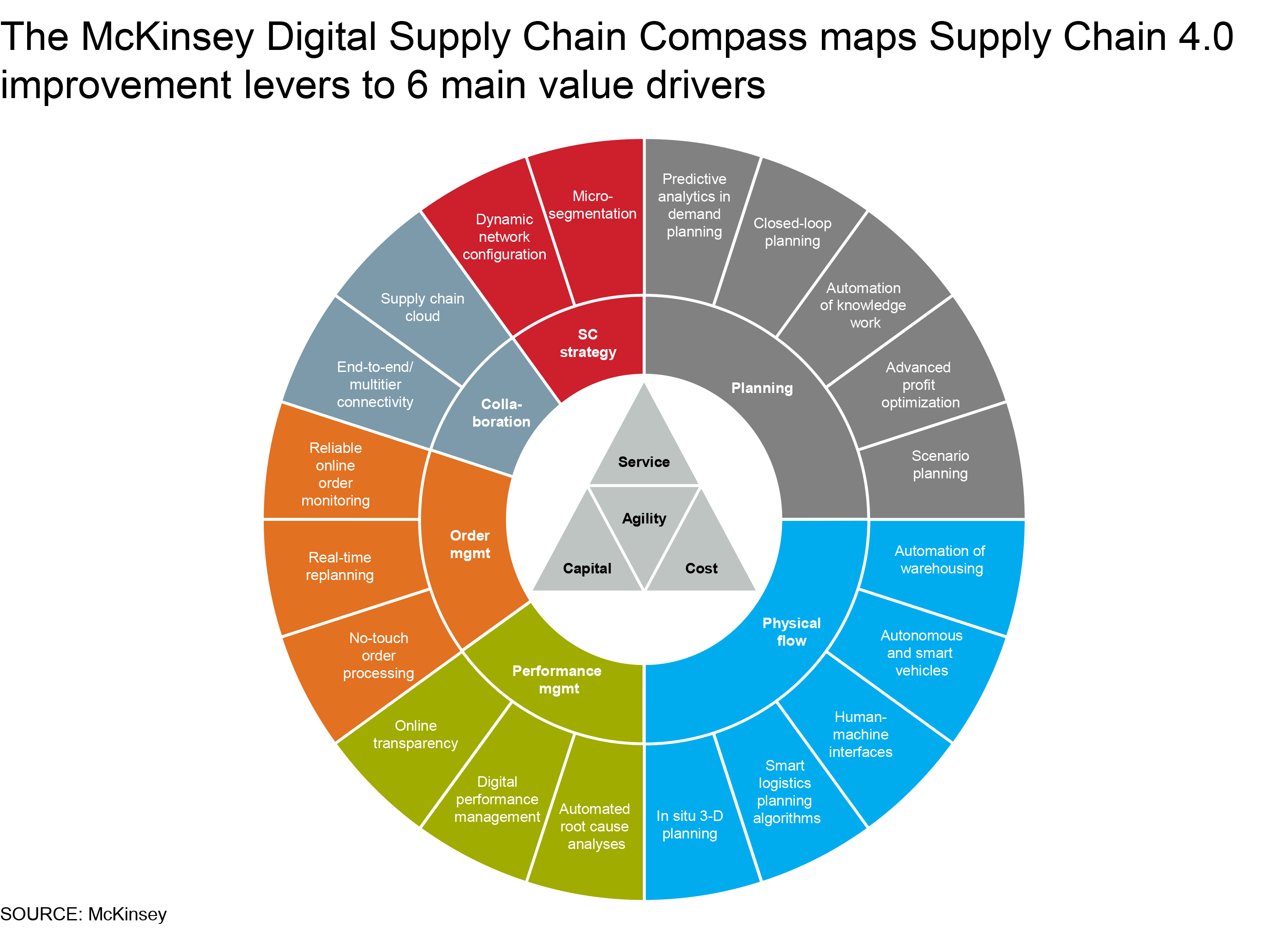

Next, there’s the Industry 4.0. – a major technical shift in how products are manufactured in the first place. And to match advances in the manufacturing sector, Supply Chain 4.0. must emerge:

Source: McKinsey

Finally, digital transformations in supply chain management do bring in some tangible benefits. Per the Amber Road report:

- 89% of digital supply chain leaders received perfect orders from international partners leading to on-time delivery.

- 68% now have complete visibility into supplier quality and manufacturing process, meaning less costly recalls.

- 12.8% gained average annual savings during the sourcing stage.

Ultimately, digitization allows supply chain managers to vastly improve their existing operations, and even forge brand new value chains by capitalizing on the latest tech.

Core Technologies Changing Supply Chain Management

Cloud computing. Cloud platforms are the backbone of any digitization process. This technology can help break the communication boundaries between different participants of the supply chain and connect them into one unified ecosystem. Migrating the IT infrastructure supporting all the supply chain processes to the cloud also gives companies additional benefits such as reduced TCOs, dynamic resource provisioning and the ability to “plug” any new entrant or tool in a matter of days, not months.

Source: Cloud Computing Concept Design Template by SlideModel

Predictive analytics. As more data will become more freely available thanks to the cloud, businesses can deploy more advanced analytics solutions that can produce more accurate insights for decision-making. Predictive analytics, powered by data mining and machine learning techniques, can eliminate the guesswork from your planning and suggest you a better course of action in near real-time. In particular, it can be effectively applied to the following processes:

- Finished inventory optimization

- Replenishment planning analytics

- Predictive maintenance

- Logistics

- Procurement analytics

- Network planning and optimization

- Production and sourcing optimizations

- Dynamic demand analytics

The Internet of Things (IoT) is becoming a popular staple in the manufacturing and logistics industries. Smart sensors can be attached to various equipment to capture a multitude of data points, ranging from its location to operational conditions. These sensors can automatically transmit the accumulated data further into your systems for analysis. For instance, with the help of IoT, you can estimate whether your goods have been transported in the right conditions. Or, when paired with predictive analytics, estimate when certain equipment is due for maintenance and order spare parts in advance to avoid costly breakdowns.

In fact, IoT has been among the most popular supply chain trends as of late with the adoption rates expecting to reach 86% over the next five years.

Source: The Internet of Things PowerPoint Template by SlideModel

Robotics and automation are seeing the most use cases in warehousing and manufacturing. The new generation of affordable collaborative robots is now working side-by-side with humans, helping with the labor-heavy tasks such as picking, sorting, inspecting, storing, handling, and classifying products. And their industrial counterparts are taking over the factory floors at an increased pace. Airbus, Adidas and Tesla are just a few examples of companies who already “employ” robots.

Individually and combined, all of these technologies have a strong potential for improving the global supply chain management. But to realize the most benefits from these, you will need to find the optimal grounds for them within your business.

How to Build a Business Case for Digitizing Supply Chain Management

Smart supply chains are powered by smart decision-making. So where does one’s foray into the digital supply chain management begins? The answer will depend on how digitally mature your current supply chain is and what benefits you’d like to seek first. And for that, you’ll need to develop a solid business case. Below is your step-by-step guide for this.

Schedule a Supply Chain Maturity Assessment

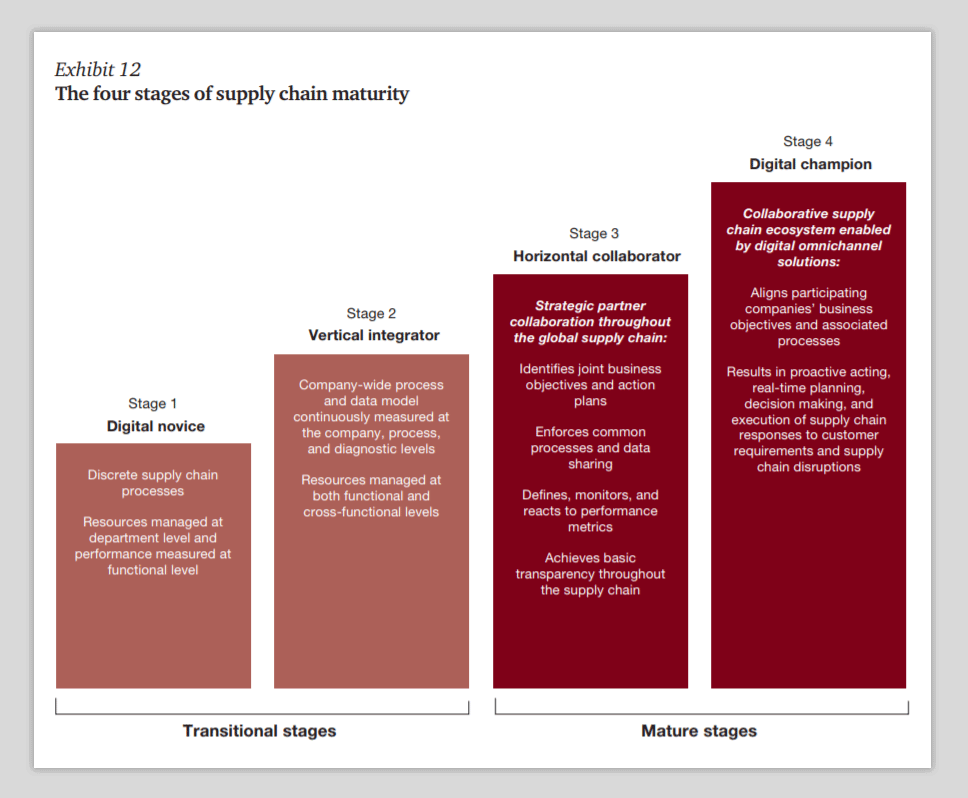

Source: PwC

Determine where you are on the maturity scale:

- Digital novice companies still have siloed supply chain processes, carried out by individual departments and business units.

- Vertical integrator companies already have solid internal supply chain processes integration, working seamlessly across departments and functions.

- Horizontal collaborators extended their integration to external partners; can effectively collaborate together on shared business goals and carry out common processes. At this stage, the supply chain is fairly transparent.

- Digital champions have achieved full transparency into their operations, have the top level of collaboration and can deploy an ecosystem-wide analytics solution to optimize the entire supply chain.

Define Your Future Vision

Speak with various stakeholders to determine a core set of benefits you’d like to achieve post-digitization. Try to work out several most promising use cases and conduct feasibility studies to determine whether the proposed technical scenarios can be executed. Afterward, create specific implementation steps and expand them into a detailed road map.

Outline How Data Will Be Integrated

To move from level 2 to level 3 maturity levels, you’ll need to create new solutions for storing, warehousing and exchanging data with 3rd parties. At the very basic level, you’ll have to work out a solid plan covering the following processes:

- Data synchronization: How will data from different remote facilities be collected? Where will it be stored? How facilities that do not have consistent Internet connections will add updated to your system and stay updated on what’s happening in other parts of your business?

- Mobile data collection: How will users in field locations or logistics personnel in the warehouse quickly and easily record and transmit data about inventory levels?

- ERP integration: How will managers see what is happening across the supply chain if data remains siloed in individual applications?

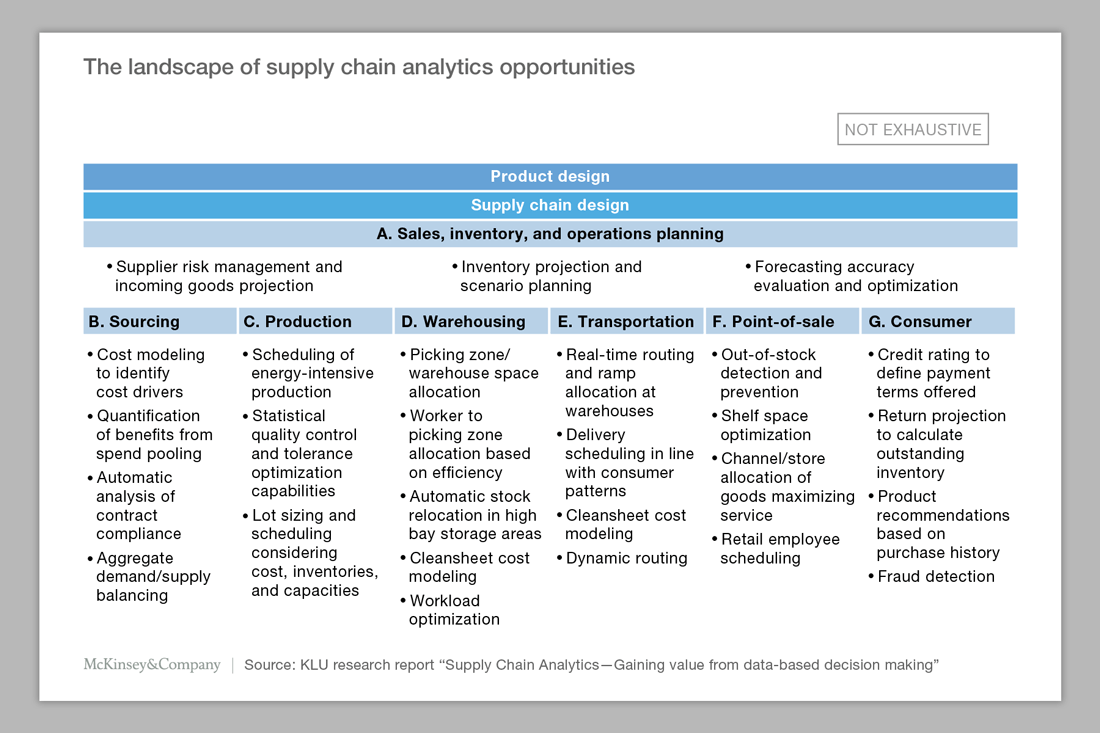

Once you create a solid organization-wide data collection processing, you can move on to exploring various supply chain analytics options that can be deployed to assist you with optimization. The choice these days is plentiful.

Source: McKinsey

Conclusions

Digitization is one of the key enablers for companies to remain successful in the next decade. Case in point: 8 of 10 supply chain leaders state that digital supply chain will become the dominant model of operations with in the next 5 years. So it’s a high time to start actively exploring new technological options (i.e., supplier management software) and building a solid business case for this. After all, the benefits are fair and square: improved efficiencies reduced operational costs and new value and revenue streams for your business. Alternatively, check our complete collection of supply chain PPT templates.