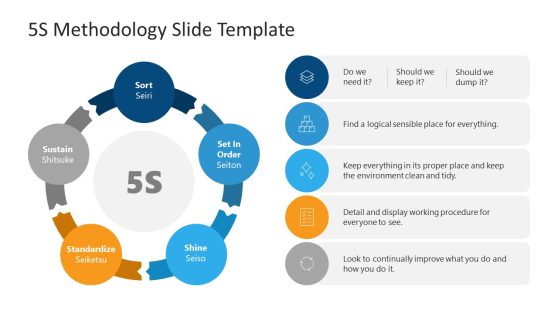

5S Diagram Template for PowerPoint

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.

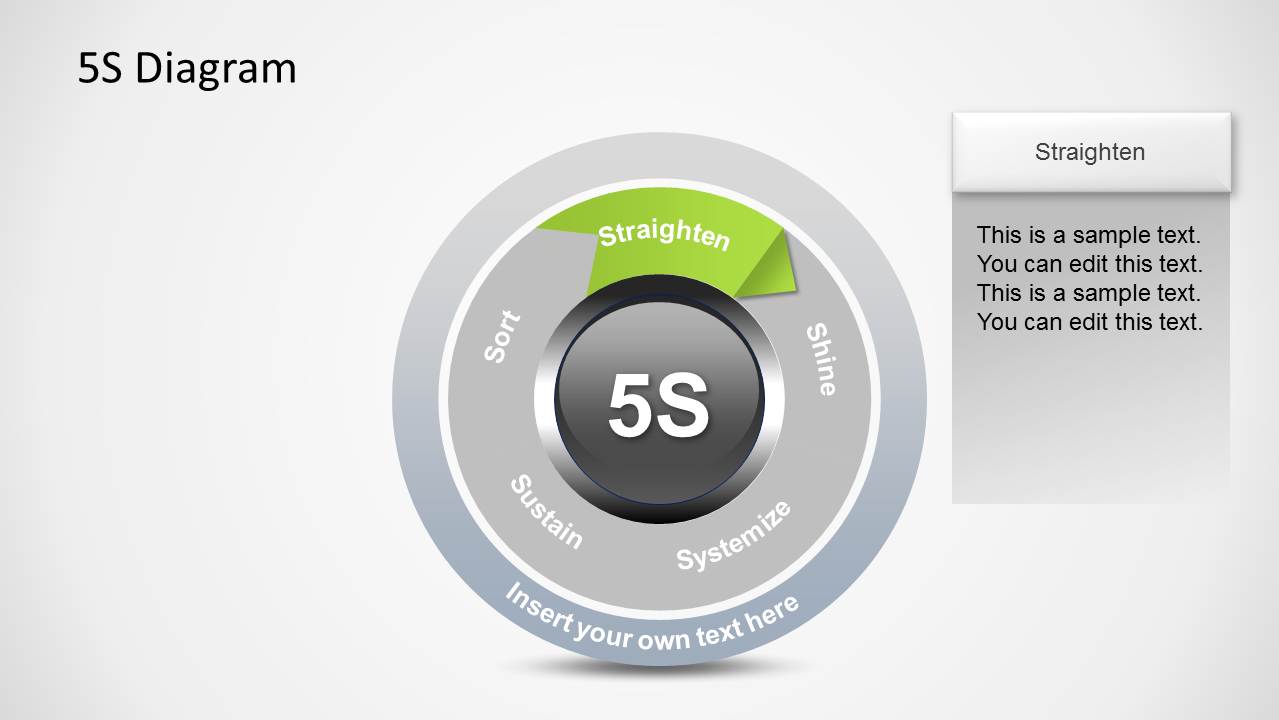

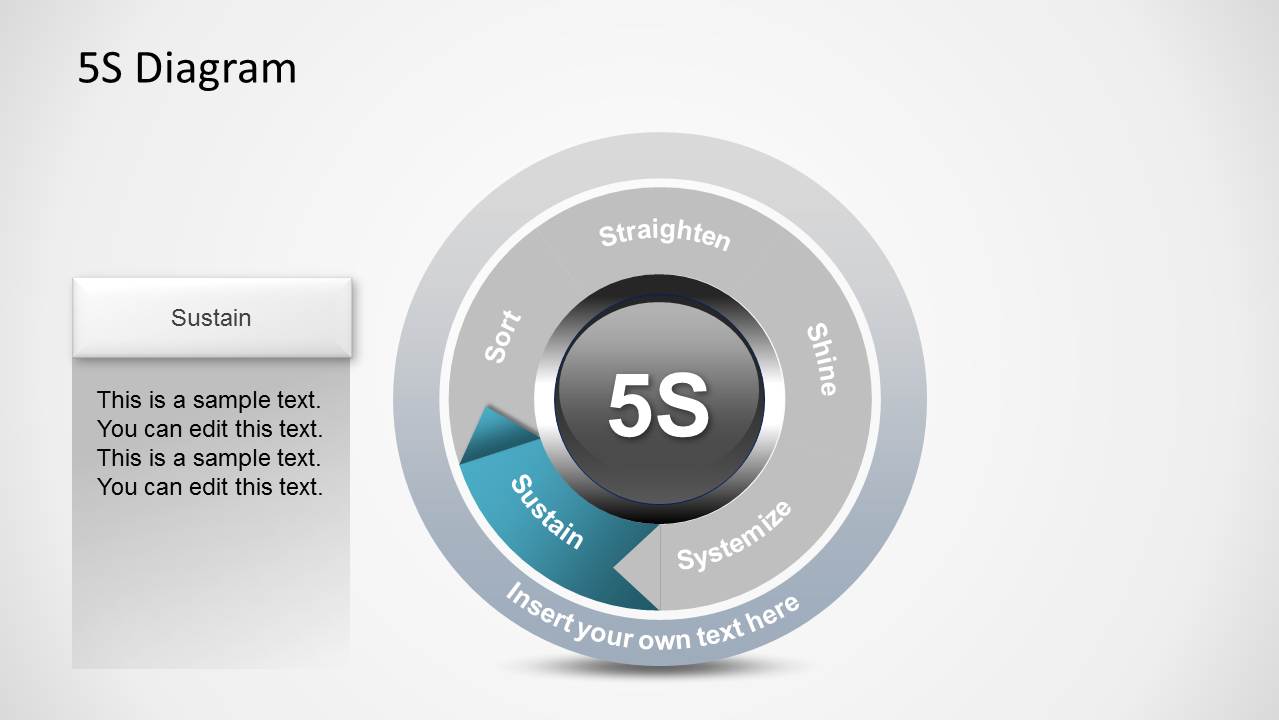

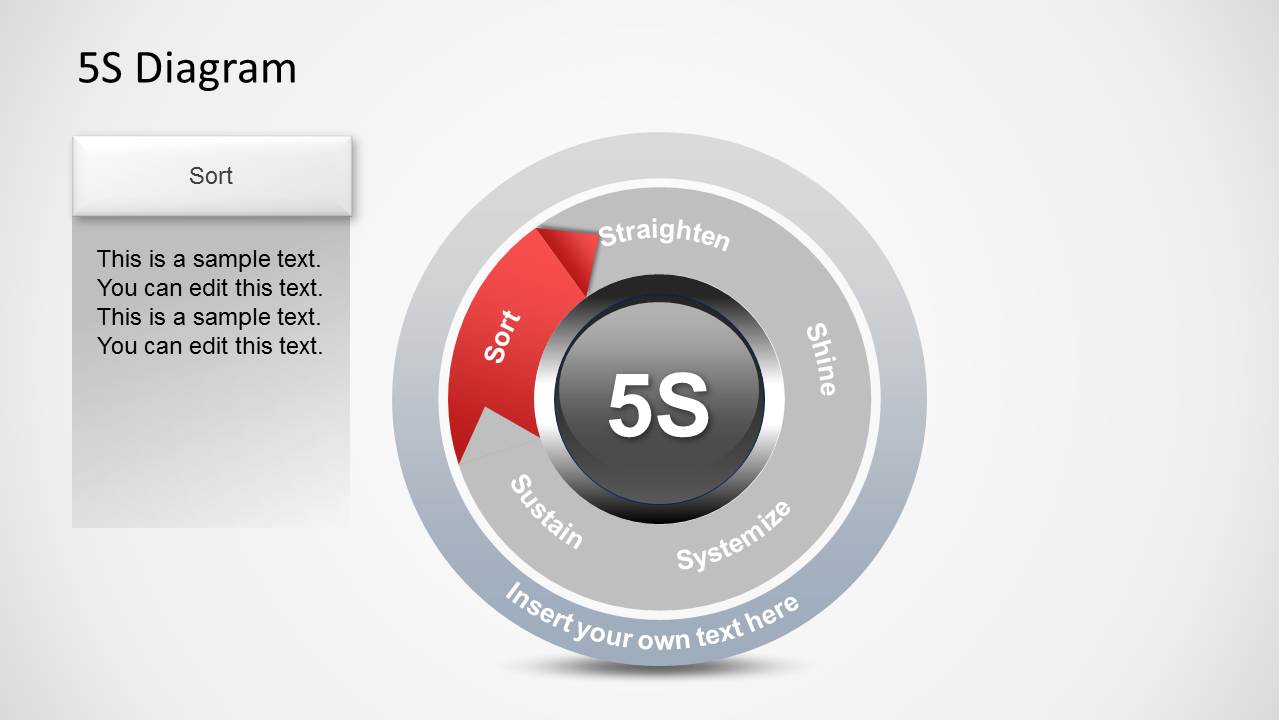

5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and Sustain. Each has its meaning, and the PowerPoint template depicts all of them in a sequence. Japanese started this concept of 5 stages, leading to the technique of Just in Time Manufacturing, one of the most used in the manufacturing industry. Different stages of the process are shown on the curved arrows.

This professional presentation template shows showing the flow of a process. The presentation template starts with an overview of the process, followed by a description of each stage. The first part elaborates on the Sort step dealing with selecting the necessary resources for the process and removing unnecessary ones. Required items can be listed in bullets for further analysis and monitoring. The next step is arranging all the resources appropriately and fully using them, the Straighten step. Shine includes the monitoring of the process and the environment around it. Systemize reflects quality inspection and modifications of the product to maintain a standard. The final stage is Sustain, which deals with storing and maintaining the products in a flow.

One thing to notice about this circular org chart template is the thin portion around the 5S diagram. It can add some text like the company’s motto or some motivational quote. The layout of this PPT template animates with each stage by focusing only on one stage at a time as the presentation goes on and dims the other stages. It completes a rotation by covering all the stages and highlighting the main points adjacent to the 5S diagram. It can also be used as a 30-60-90-day plan template, with each curved arrow showing a regular interval of some days to make a project timeline.